EMI Shielding Materials Market Size, Share, Outlook, and Opportunity Analysis, 2022 - 2030

EMI Shielding Materials Market

The EMI (electromagnetic

interference) shielding materials market has been rapidly growing in recent

years. As electronic devices become more prevalent in our daily lives, the need

for effective EMI shielding materials has increased. EMI shielding materials

are used to protect electronic devices from interference caused by

electromagnetic waves, which can cause disruption or damage to the device's

performance. In this article, we will explore the growth of the EMI shielding

materials market, the different types of EMI shielding materials, and the key

factors driving the market.

The EMI

shielding materials market is projected to grow at a compound annual

growth rate (CAGR) of over 5% from 2021 to 2026. This growth is due to the

increasing use of electronic devices in various applications, such as

automotive, aerospace, telecommunications, and healthcare. The automotive

sector is expected to be the largest end-user of EMI shielding materials, as

cars become more reliant on electronic systems, including infotainment systems,

advanced driver assistance systems, and autonomous driving technology.

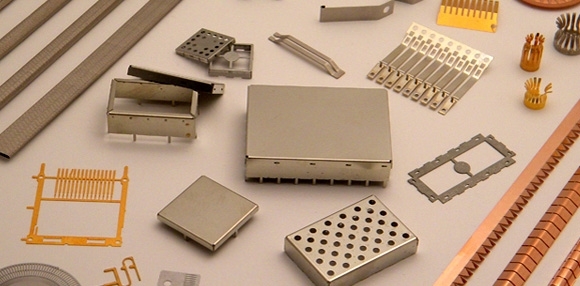

There are several types of EMI

shielding materials available in the market, including conductive coatings,

conductive tapes, conductive fabrics, conductive plastics, metal sheets, and

others. Conductive coatings, which are applied directly to the surface of

electronic devices, are the most commonly used EMI shielding materials. These

coatings can be made from various materials, such as silver, copper, nickel,

and graphite, and provide a low-resistance path for electromagnetic waves to

flow through, reducing interference.

Conductive tapes and fabrics are

also commonly used as EMI

Shielding Materials Market. These materials are flexible and can

be easily applied to the surface of electronic devices or incorporated into

electronic systems. Conductive tapes and fabrics are often made from metalized

fabrics or conductive polymers, which provide a high level of EMI shielding.

Conductive plastics are another

type of EMI shielding material that has gained popularity in recent years.

These plastics contain conductive particles, such as carbon or metal, which

provide a low-resistance path for electromagnetic waves to flow through. Conductive

plastics are lightweight, durable, and can be easily molded into different

shapes and sizes, making them suitable for a wide range of electronic

applications.

Comments

Post a Comment